Note

Go to the end to download the full example code.

Static simulation of double cantilever beam test via cohesive elements#

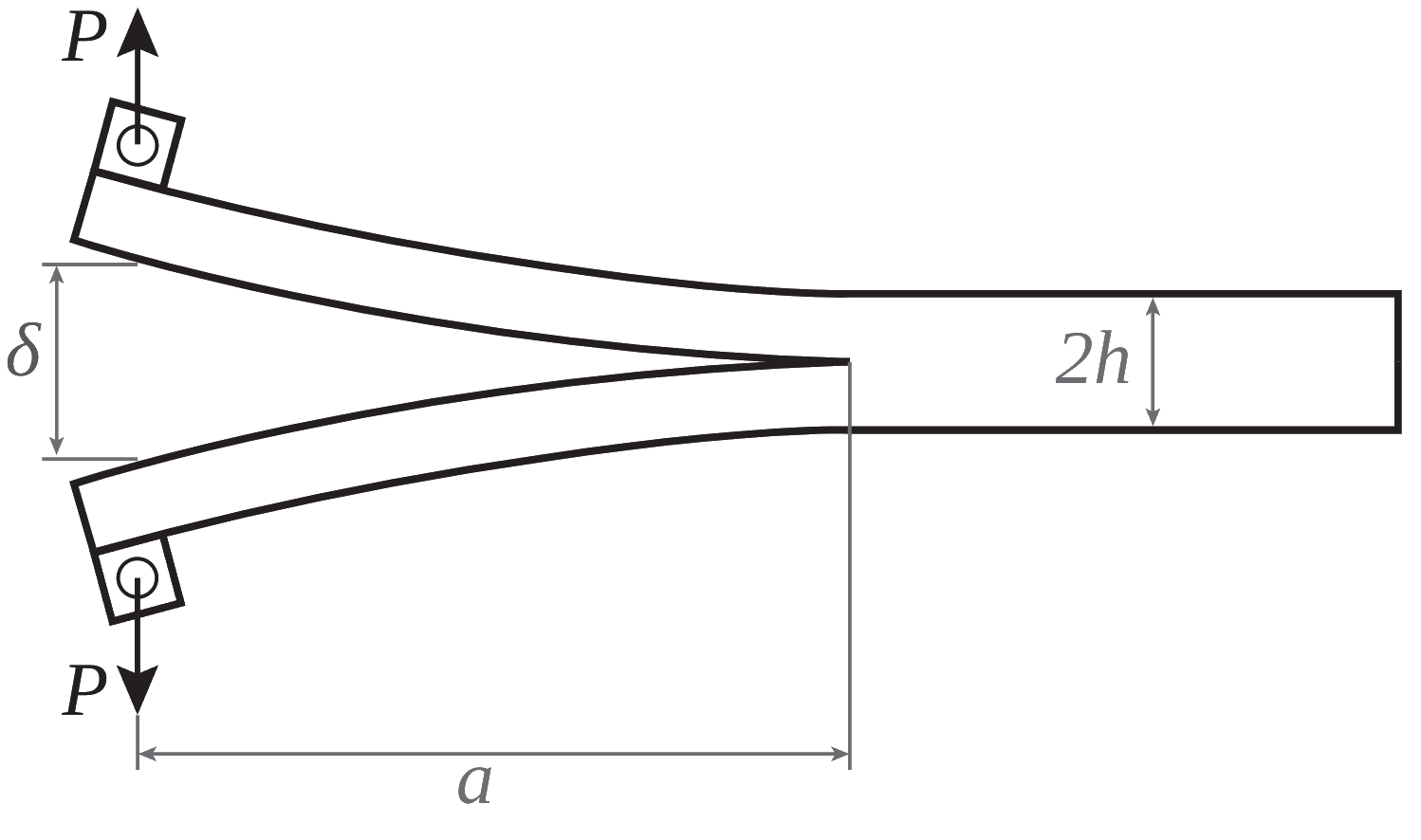

This example is a classic double cantilever beam test commonly used to study mode I interfacial delamination of composite plates.

Description#

Objective#

This example shows how to use PyMAPDL to simulate delamination in composite materials. PyDPF modules are also used for the postprocessing of the results.

Problem figure#

Procedure#

Launch the MAPDL instance.

Set up the model.

Solve the model.

Plot results using PyMAPDL.

Plot results using PyDPF.

Plot reaction force.

Additional packages#

These additional packages are imported for use: * - Matplotlib for plotting * - Pandas for data analysis and manipulation

Start MAPDL as a service#

This example begins by importing the required packages and then launching Ansys Mechanical APDL.

import os

import tempfile

from ansys.dpf import core as dpf

import matplotlib.pyplot as plt

import numpy as np

import pyvista as pv

from ansys.mapdl.core import launch_mapdl

# Start MAPDL as a service

mapdl = launch_mapdl()

print(mapdl)

Mapdl

-----

PyMAPDL Version: 0.72.1

Interface: grpc

Product: Ansys Mechanical Enterprise

MAPDL Version: 25.2

Running on: localhost

(127.0.0.1)

Set geometrical inputs#

Set geometrical inputs for the model.

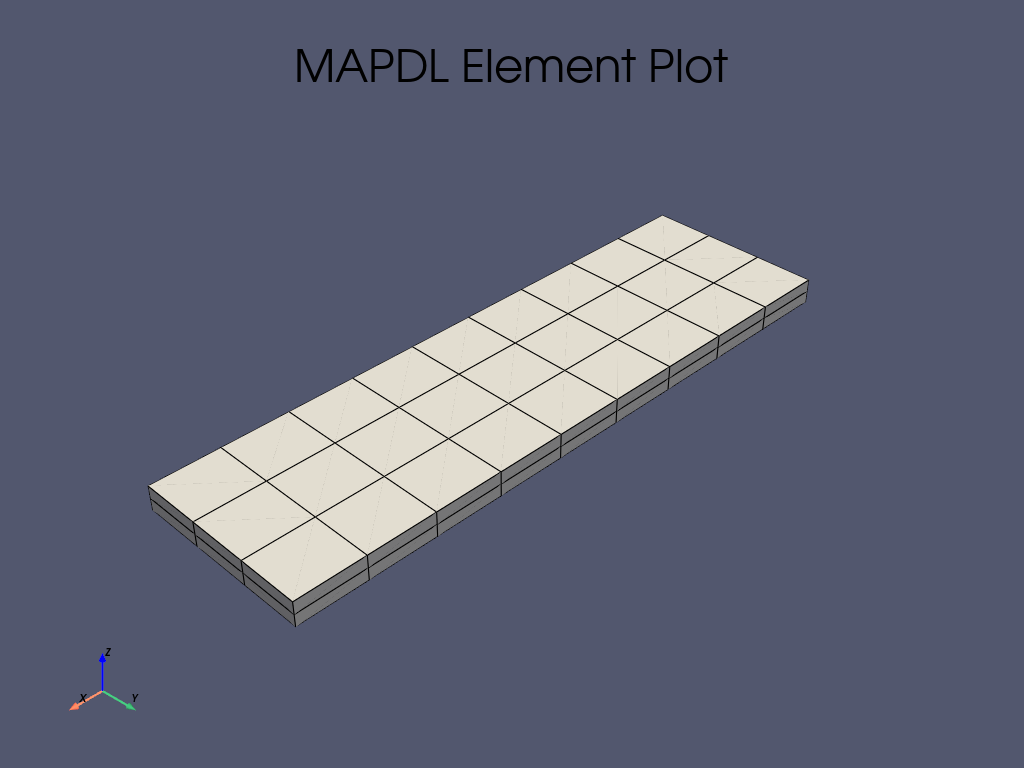

Set up the model#

Set up the model by choosing the units system and the

element types for the simulations. Because a fully 3D approach

is chosen for this example, SOLID186 elements are used for meshing volumes, and

TARGE170 and CONTA174 are used for modelling cohesive elements in between contact

surfaces.

Define material parameters#

Composite plates are modelled using homogeneous linear elastic orthotropic properties, whereas a bilinear cohesive law is used for cohesive elements.

# Enter the preprocessor and define the unit system

mapdl.prep7()

mapdl.units("mpa")

# Define SOLID185, TARGE170, and CONTA174 elements, along with the element size

mapdl.et(1, 185)

mapdl.et(2, 170)

mapdl.et(3, 174)

mapdl.esize(10.0)

# Define material properties for the composite plates

mapdl.mp("ex", 1, 61340)

mapdl.mp("dens", 1, 1.42e-09)

mapdl.mp("nuxy", 1, 0.1)

# Define the bilinear cohesive law

mapdl.mp("mu", 2, 0)

mapdl.tb("czm", 2, 1, "", "bili")

mapdl.tbtemp(25.0)

mapdl.tbdata(1, 50.0, 0.5, 50, 0.5, 0.01, 2)

DATA FOR CZM TABLE FOR MATERIAL 2 AT TEMPERATURE= 25.0000

LOC= 1 5.00000e+01 5.00000e-01 5.00000e+01 5.00000e-01 1.00000e-02 2.00000e+00

Create the geometry in the model and meshing#

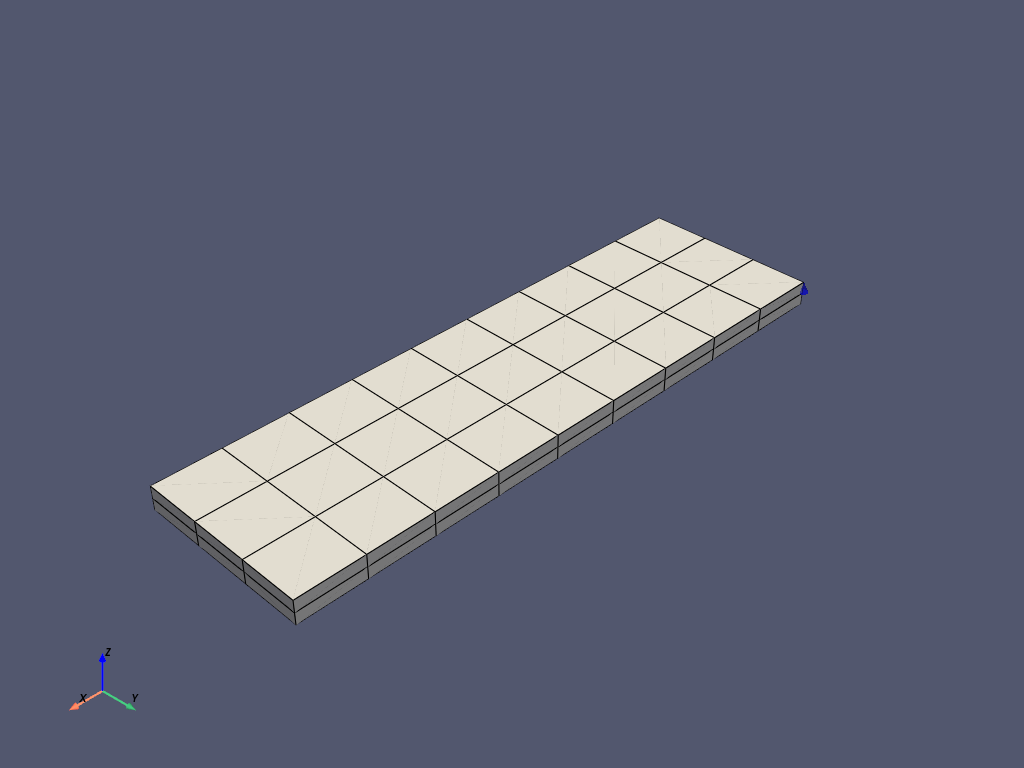

The two plates are generated as two parallelepipeds. Composite material properties and the three-dimensional elements are then assigned.

# Generate the two composite plates

vnum0 = mapdl.block(0.0, length + pre_crack, 0.0, width, 0.0, height)

vnum1 = mapdl.block(0.0, length + pre_crack, 0.0, width, height, 2 * height)

# Assign material properties and element type

mapdl.mat(1)

mapdl.type(1)

# performing the meshing

mapdl.vmesh(vnum0)

mapdl.vmesh(vnum1)

mapdl.esel("all")

mapdl.eplot()

Generate cohesive elements in between the contact surfaces#

The generation of cohesive elements is the most delicate part of the

modelling approach. First, the two contact surfaces are identified

and defined as a components (in this case cm_1 and cm_2 respectively).

Then, the real constants for the CONTA174 and TARGE170 elements and

their key options are set to capture the correct behavior. Descriptions for each

of these parameters can be found in the Ansys element documentation.

Finally, elements are generated on top of the respective surfaces cm_1 and

cm_2.

# Identify the two touching areas and assign them to components

mapdl.allsel()

mapdl.asel("s", "loc", "z", 1.7)

mapdl.asel("r", vmin=mapdl.geometry.anum[0])

mapdl.nsla("r", 1)

mapdl.nsel("r", "loc", "x", pre_crack, length + pre_crack + eps)

mapdl.components["cm_1"] = "node"

mapdl.allsel()

mapdl.asel("s", "loc", "z", 1.7)

mapdl.asel("r", vmin=mapdl.geometry.anum[1])

mapdl.nsla("r", 1)

mapdl.nsel("r", "loc", "x", pre_crack, length + pre_crack + eps)

mapdl.components["cm_2"] = "node"

# Identify all the elements before generation of TARGE170 elements

mapdl.allsel()

mapdl.components["_elemcm"] = "elem"

mapdl.mat(2)

# Assign real constants and key options

mapdl.r(3, "", "", 1.0, 0.1, 0, "")

mapdl.rmore("", "", 1.0e20, 0.0, 1.0, "")

mapdl.rmore(0.0, 0.0, 1.0, "", 1.0, 0.5)

mapdl.rmore(0.0, 1.0, 1.0, 0.0, "", 1.0)

mapdl.rmore("", "", "", "", "", 1.0)

mapdl.keyopt(3, 4, 0)

mapdl.keyopt(3, 5, 0)

mapdl.keyopt(3, 7, 0)

mapdl.keyopt(3, 8, 0)

mapdl.keyopt(3, 9, 0)

mapdl.keyopt(3, 10, 0)

mapdl.keyopt(3, 11, 0)

mapdl.keyopt(3, 12, 3)

mapdl.keyopt(3, 14, 0)

mapdl.keyopt(3, 18, 0)

mapdl.keyopt(3, 2, 0)

mapdl.keyopt(2, 5, 0)

# Generate TARGE170 elements on top of cm_1

mapdl.nsel("s", "", "", "cm_1")

mapdl.components["_target"] = "node"

mapdl.type(2)

mapdl.esln("s", 0)

mapdl.esurf()

# Generate CONTA174 elements on top of cm_2

mapdl.cmsel("s", "_elemcm")

mapdl.nsel("s", "", "", "cm_2")

mapdl.components["_contact"] = "node"

mapdl.type(3)

mapdl.esln("s", 0)

mapdl.esurf()

GENERATE ELEMENTS ON SURFACE DEFINED BY SELECTED NODES

TYPE= 3 REAL= 1 MATERIAL= 2 ESYS= 0

NUMBER OF ELEMENTS GENERATED= 21

Generate boundary conditions#

Assign boundary conditions to replicate the real test conditions. One end of the two

composite plates is fixed against translation along the x, y, and z axis. On the

opposite side of the plate, displacement conditions are applied to

simulate the interfacial crack opening. These conditions are applied to the

top and bottom nodes corresponding to the geometrical edges located

respectively at these (x, y, z) coordinates:, (0.0, `y`, 0.0) and (0.0, `y`, 3.4).

Two different components are assigned to these sets of nodes for a faster

identification of the nodes bearing reaction forces.

# Apply the two displacement conditions

mapdl.allsel()

mapdl.nsel(type_="s", item="loc", comp="x", vmin=0.0, vmax=0.0)

mapdl.nsel(type_="r", item="loc", comp="z", vmin=2 * height, vmax=2 * height)

mapdl.d(node="all", lab="uz", value=d)

mapdl.components["top_nod"] = "node"

mapdl.allsel()

mapdl.nsel(type_="s", item="loc", comp="x", vmin=0.0, vmax=0.0)

mapdl.nsel(type_="r", item="loc", comp="z", vmin=0.0, vmax=0.0)

mapdl.d(node="all", lab="uz", value=-10)

mapdl.components["bot_nod"] = "node"

mapdl.allsel()

mapdl.eplot(

plot_bc=True,

bc_glyph_size=3,

title="Applied displacements",

cpos=[-1, 1, 1],

)

# Apply the fix condition

mapdl.allsel()

mapdl.nsel(

type_="s",

item="loc",

comp="x",

vmin=length + pre_crack,

vmax=length + pre_crack,

)

mapdl.d(node="all", lab="ux", value=0.0)

mapdl.d(node="all", lab="uy", value=0.0)

mapdl.d(node="all", lab="uz", value=0.0)

mapdl.allsel()

mapdl.eplot(

plot_bc=True,

bc_glyph_size=3,

title="Fixed boundary condition",

)

Solve the non-linear static analysis#

Run a non-linear static analysis. To have smooth crack opening progression and facilitate convergency for the static solver, request 100 substeps.

# Enter the solution processor and define the analysis settings

mapdl.allsel()

mapdl.finish()

mapdl.solution()

mapdl.antype("static")

# Activate non-linear geometry

mapdl.nlgeom("on")

# Request substeps

mapdl.autots(key="on")

mapdl.nsubst(nsbstp=100, nsbmx=100, nsbmn=100)

mapdl.kbc(key=0)

mapdl.outres("all", "all")

# Solve

output = mapdl.solve()

Postprocessing#

Use PyMAPDL and PyDPF for postprocessing.

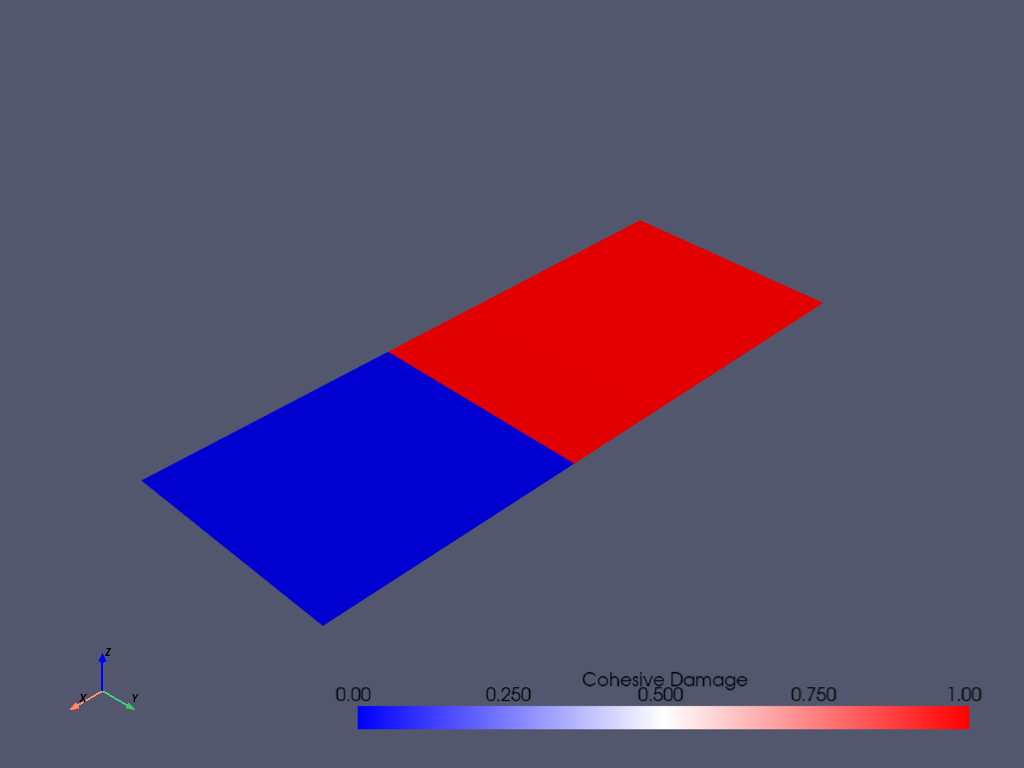

Postprocess results using PyMAPDL#

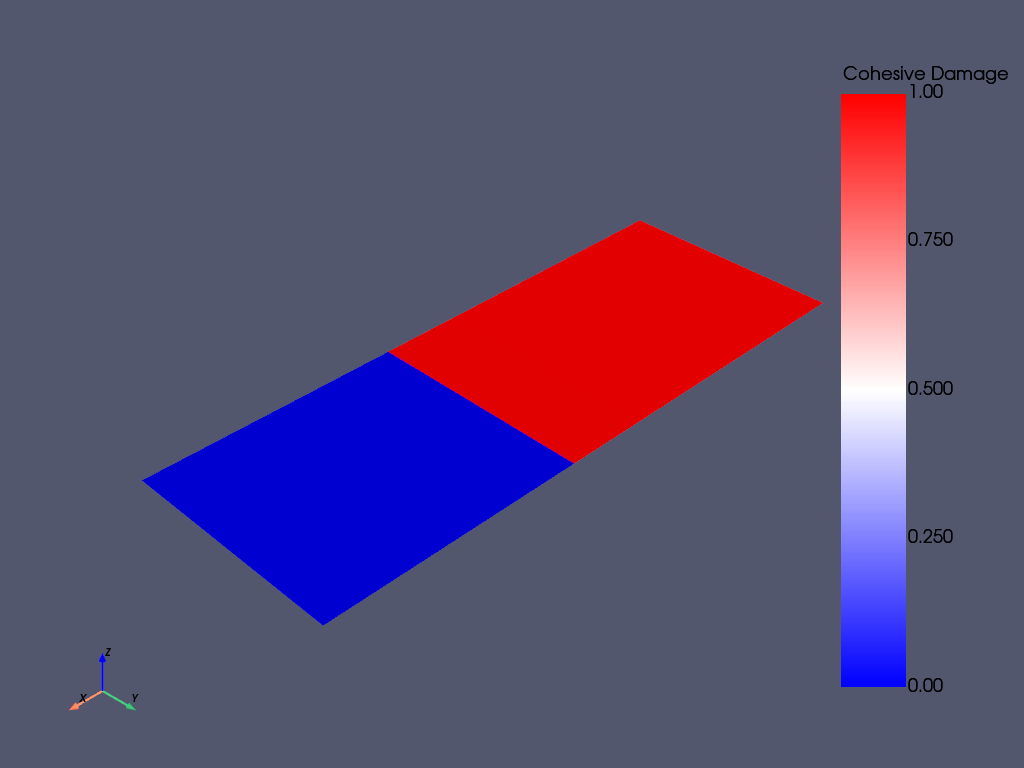

This section shows how to use PyMAPDL to postprocess results. Because

measuring the delamination length is important, plot the cohesive damage parameter.

Although the damage parameter is an element parameter, the result is

provided in terms of a nodal result. Thus, the result for just one of

the four-noded cohesive element NMISC = 70 is presented.

The result for the other nodes are present at NMISC = 71,72,73.

You can retrieve the actual damage parameter nodal values from the

solved model in form of a table (or an array).

# Enter the postprocessor

mapdl.post1()

# Select the substep

mapdl.set(1, 100)

# Select ``CONTA174`` elements

mapdl.allsel()

mapdl.esel("s", "ename", "", 174)

# Plot the element values

mapdl.post_processing.plot_element_values(

"nmisc", 70, scalar_bar_args={"title": "Cohesive Damage"}

)

# Extract the nodal values of the damage parameter

mapdl.allsel()

mapdl.esel("s", "ename", "", 174)

mapdl.etable("damage", "nmisc", 70)

damage_df = mapdl.pretab("damage").to_dataframe()

Postprocessing results using PyDPF#

Use PyDPF to visualize the crack opening throughout the simulation as an animation.

temp_directory = tempfile.gettempdir()

rst_path = mapdl.download_result(temp_directory)

server_is_local = "DPF_PORT" not in os.environ

if server_is_local:

# Local server

dpf_server = dpf.server.start_local_server()

path_source = rst_path

else:

# Remote server

dpf_server = dpf.server.connect_to_server(port=int(os.environ["DPF_PORT"]))

path_source = dpf.upload_file_in_tmp_folder(rst_path)

os.remove(rst_path) # Delete local copy

# Building the model

model = dpf.Model(path_source, dpf_server)

# Get the mesh of the whole model

meshed_region = model.metadata.meshed_region

# Get the mesh of the cohesive elements

mesh_scoping_cohesive = dpf.mesh_scoping_factory.named_selection_scoping(

"CM_1", model=model

)

result_mesh = dpf.operators.mesh.from_scoping(

scoping=mesh_scoping_cohesive, inclusive=0, mesh=meshed_region

).eval()

# Get the coordinates field for each mesh

mesh_field = meshed_region.field_of_properties(dpf.common.nodal_properties.coordinates)

mesh_field_cohesive = result_mesh.field_of_properties(

dpf.common.nodal_properties.coordinates

)

# Get the index of the NMISC results

nmisc_index = 70

# Generate the damage result operator

data_src = dpf.DataSources(path_source)

dam_op = dpf.operators.result.nmisc(data_sources=data_src, item_index=70)

# Generate the displacement operator

disp_op = model.results.displacement()

# Create sum operators to compute the updated coordinates at step n

add_op = dpf.operators.math.add(fieldA=mesh_field)

add_op_cohesive = dpf.operators.math.add(fieldA=mesh_field_cohesive)

# Instantiate a PyVista plotter and start the creation of a GIF

plotter = pv.Plotter(notebook=False, off_screen=True)

plotter.open_gif("dcb.gif")

# Add the beam mesh to the scene

mesh_beam = meshed_region.grid

plotter.add_mesh(

mesh_beam,

lighting=False,

show_edges=True,

scalar_bar_args={"title": "Cohesive Damage"},

clim=[0, 1],

opacity=0.3,

)

# Add the contact mesh to the scene

mesh_contact = result_mesh.grid

plotter.add_mesh(

mesh_contact,

opacity=0.9,

scalar_bar_args={"title": "Cohesive Damage"},

clim=[0, 1],

scalars=np.zeros((mesh_contact.n_cells)),

)

for i in range(1, 100):

# Get displacements

disp = model.results.displacement(time_scoping=i).eval()

# Getting the updated coordinates

add_op.inputs.fieldB.connect(disp[0])

disp_result = add_op.outputs.field()

# Get displacements for the cohesive layer

disp = model.results.displacement(

time_scoping=i, mesh_scoping=mesh_scoping_cohesive

).eval()

# Get the updated coordinates for the cohesive layer

add_op_cohesive.inputs.fieldB.connect(disp[0])

disp_cohesive = add_op_cohesive.outputs.field()

# Get the damage field

dam_op.inputs.time_scoping([i])

cohesive_damage = dam_op.outputs.fields_container()[0]

# Update coordinates and scalars

mesh_beam.points = disp_result.data

mesh_contact.points = disp_cohesive.data

plotter.update_scalars(cohesive_damage.data, mesh=mesh_contact, render=False)

plotter.write_frame()

plotter.close()

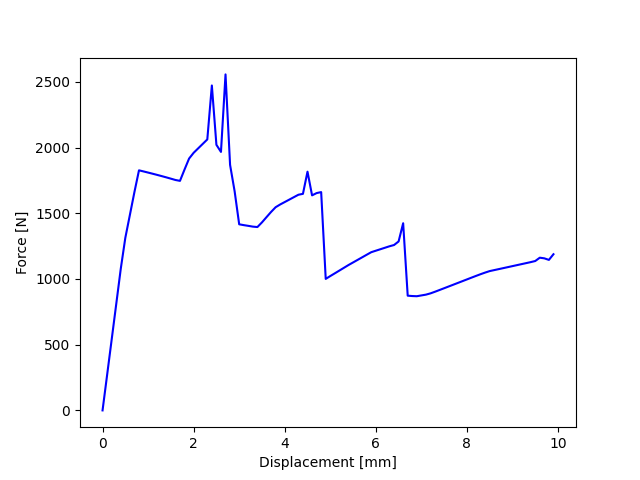

Plot the reaction force at the bottom nodes

mesh_scoping = model.metadata.named_selection("BOT_NOD")

f_tot = []

d_tot = []

for i in range(100):

force_eval = model.results.element_nodal_forces(

time_scoping=i, mesh_scoping=mesh_scoping

).eval()

force = force_eval[0].data

f_tot += [np.sum(force[:, 2])]

d = abs(

model.results.displacement(time_scoping=i, mesh_scoping=mesh_scoping)

.eval()[0]

.data[0]

)

d_tot += [d[2]]

d_tot[0] = 0

f_tot[0] = 0

fig, ax = plt.subplots()

plt.plot(d_tot, f_tot, "b")

plt.ylabel("Force [N]")

plt.xlabel("Displacement [mm]")

plt.show()

Animate results using PyDPF with .animate() method#

Use PyDPF method FieldsContainer.animate() to visualize the crack opening throughout the simulation as

an animation.

disp = model.results.displacement.on_all_time_freqs.eval()

camera_pos = disp.animate(

scale_factor=1.0,

save_as="dcb_animate.gif",

return_cpos=True,

show_axes=True,

)

Exit MAPDL

mapdl.exit()

Total running time of the script: (1 minutes 5.908 seconds)